|

|

Whistler was a graduate of West Point, the nations first engineering school. In the early days of this institution, study was standardized. All cadets studied the same thing. Bridge building was part of this curriculum. While at age 28, Whistler worked on Americas first railroad, the Baltimore and Ohio, much of his early career was spent designing canals, those at Stoning CT, and Lowell MA among them. The 1830s were still the age of canals. It was difficult to raise funds for railroads as they were considered as yet unproved, something of a novelty. The standards of the Western Railroad were set very high by Whistler. How high was largely unfathomable to supporters of the project, as there was little to compare them to. Investors pushed for a single-track line to save money, Whistler insisted on double. All cuts and bridges were built to double track width, though only a single track was initially laid. Within a decade, traffic mandated the second track. When built, it was so steep no locomotives existed able to climb the grade. Horse towing or stationary winches were considered.

Engineering of

stone arches was, by the 1830', a well-established procedure. The oldest known arch still in use is believed to be in China, erected in 610 AD. While this would seem to make arch building technology somewhat mundane by 1835, it was still a painstaking and very expensive method of bridge construction. Therefore, they were chosen for only the most remote locations in the belief that the elimination of periodic maintenance would justify the added expense. Illustrative of this mentality, the CT River bridge, then the longest in the world, was originally constructed of wood. With its close proximity to the large shops of West Springfield, it could easily be repaired if needed. The Ct River bridge was seven spans long, 180 feet each, or 1264 feet long. It was built at a cost of $ 131, 612.12. It opened on July 4, 1841; two months after trains began running over the whole of the western portion of the line.

|

||

|

On the point avoiding maintenance, the keystone arches of Becket, Chester and Middlefield have surpassed all expectations of their builders. The examples here still in use carry trains 40 times heavier than they were designed for. In 1830, a steam locomotive weighed about 12,000 lbs. The average locomotive of 2003 weighs in the neighborhood of 415,000 lbs. Those arches bypassed in the line relocation of 1912 have stood as of this writing for 91 years with no maintenance whatsoever. Few bridges built today will stand for 91 years under any circumstances. The first locomotives bought by the road were from the Locks and Canals Co., of Lowell, MA, a product of Maj. Whistler. They werent great performers, but they put the thought of horses or winches out of mind. They were of a 2-2-0 wheel arrangement and weighed 12 tons each. They were not heavy enough for the climb, but were good engines and were sold to other railroads where they served long careers. Whistler consulted with famed locomotive builder, Ross Winans. He purchased seven locomotives, eight wheels coupled, called Crabs, due to the unique motion of the valve gear. They weighed in at 22.5 tons and cost $11,000.00 each. Throughout the history of the road, larger and more powerful locomotives made their debuts. The increasing lengths of trains and size of the cars mandated ever-larger engines. In a sense, operators of the line are still searching for enough power. The 6000 hp locomotives of 2003 are still working all out as they assault the hill. Various operators of the property have tried different strategies to move the tonnage. Until the late 70s pushers were popular on the rear of trains. As horsepower increased, the pushers disappeared. During the Penn Central years, track maintenance dwindled to a point where trains were limited to 25 mph. CONRAIL brought the physical plant back up to standards where a good run on the hill was a possibility, thus train length increased. CONRAIL was also responsible for trimming the line to essentially single track, although the hill remains double; it is considered a passing siding. This plan actually dates to the mid-fifties, where it is seen contemplated in the NYC employee magazine. According to CSX officials in Selkirk last spring, the line will never be doubled again. The plan is working for them. CSX prefers shorter, faster trains, with fewer locomotives. It remains a widely held misconception that this is the steepest grade in the east. In fact, by todays standards, it is comparatively mild at 1.65%. The percentage of curvature (52%) does make it a tricky run for locomotive engineers. It is said that an engineer employed here for a couple of years can get a job on any railroad in the country thereafter. The steepest, or ruling grade is on the western side. The summit is reached in only six miles as opposed to ten miles on the eastern slope.

|

|||

|

7.

Haunch

- The part of the arch's wall which experiences the most thrust

8. Crown - The top part of an arch |

|||

|

|

|||

How did they do that?Before construction began, the height of the bridge was determined by track elevation previously gained.

|

|||

|

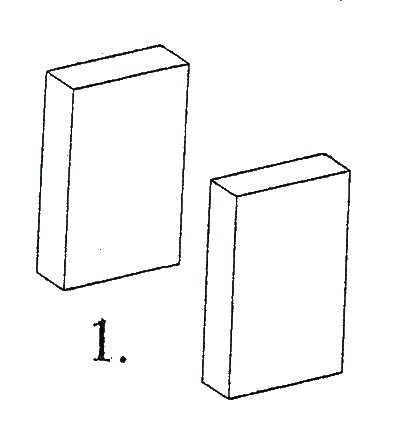

S tep 1. The two support walls were constructed to what would become the "spring line" from whence springs the curvature.

|

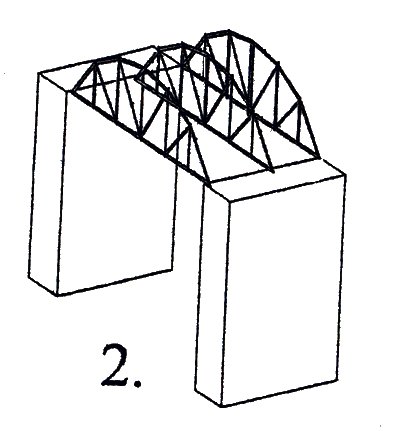

Step 2. The final course of stone is extended to support a scaffold constructed in the shape of an arch.

|

||

|

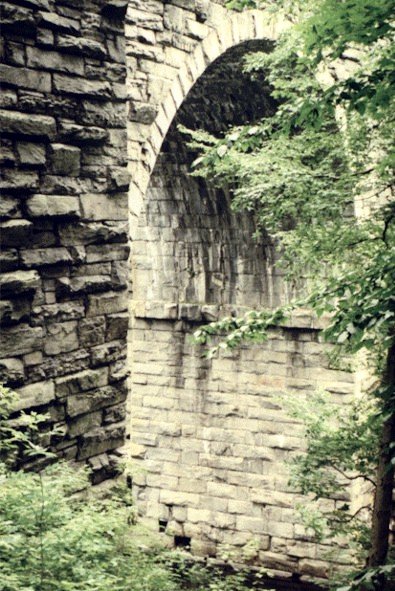

This photo shows an arch where the extended course of stone that held the scaffold is still clearly visible: |

|

||

|

3. The outer side is covered with planking

|

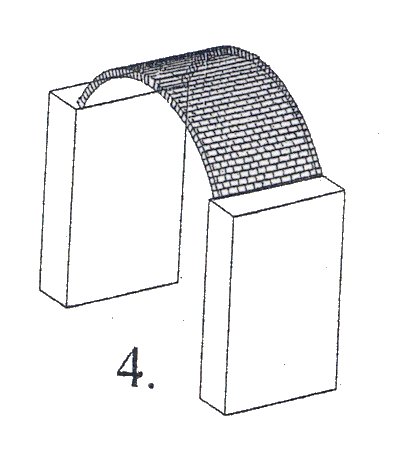

4. Stone courses are laid on the "roof" of the scaffold. When the sides meet and the Keystone course is laid, each side supports the other. |

||

|

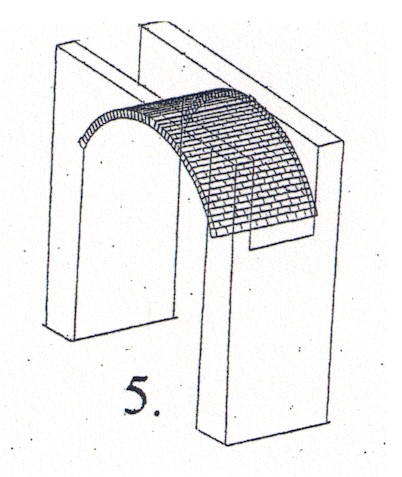

5. With the aid of a spindly trestle track is set at the proper height from which is dumped fill, to assume the final berm shape with retaining walls (to the left in figure 5). Walls which will become the sides of the bridge are constructed.

|

|

||

|

|

|||

|

The photo below is a close up of a Key Stone.

|

|||